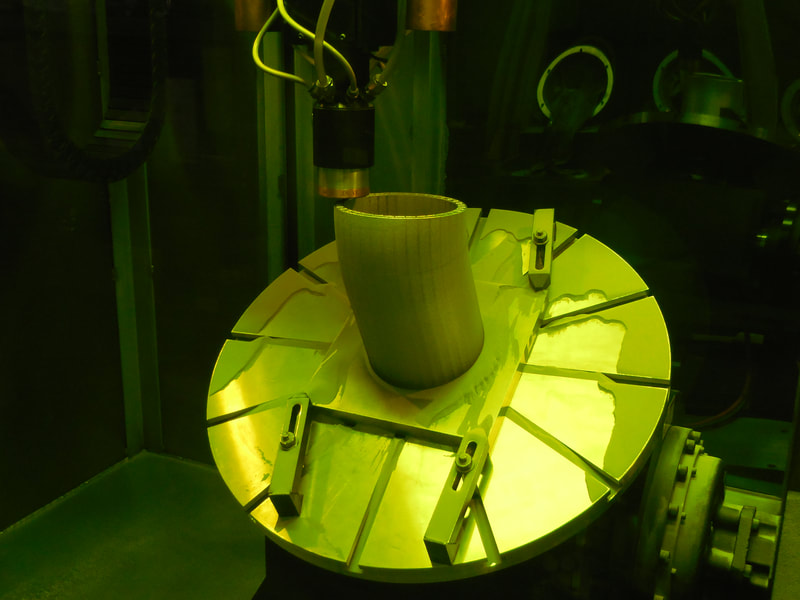

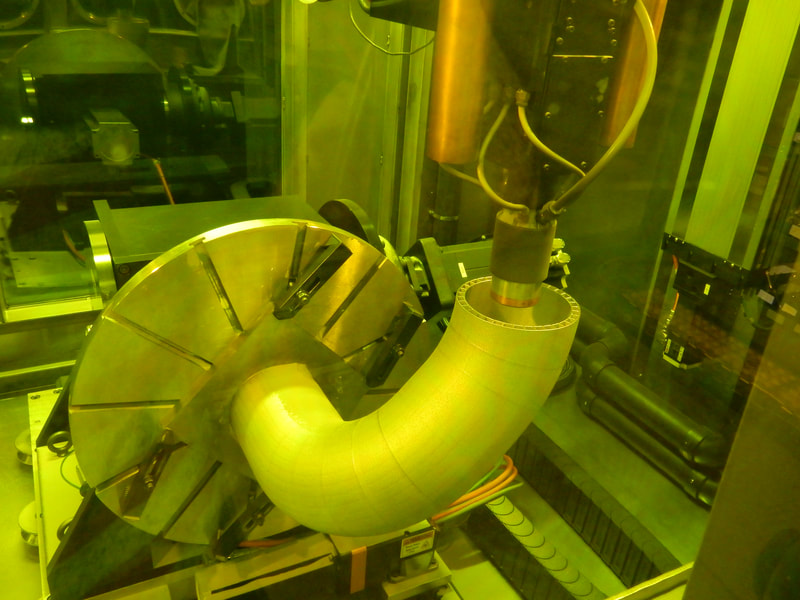

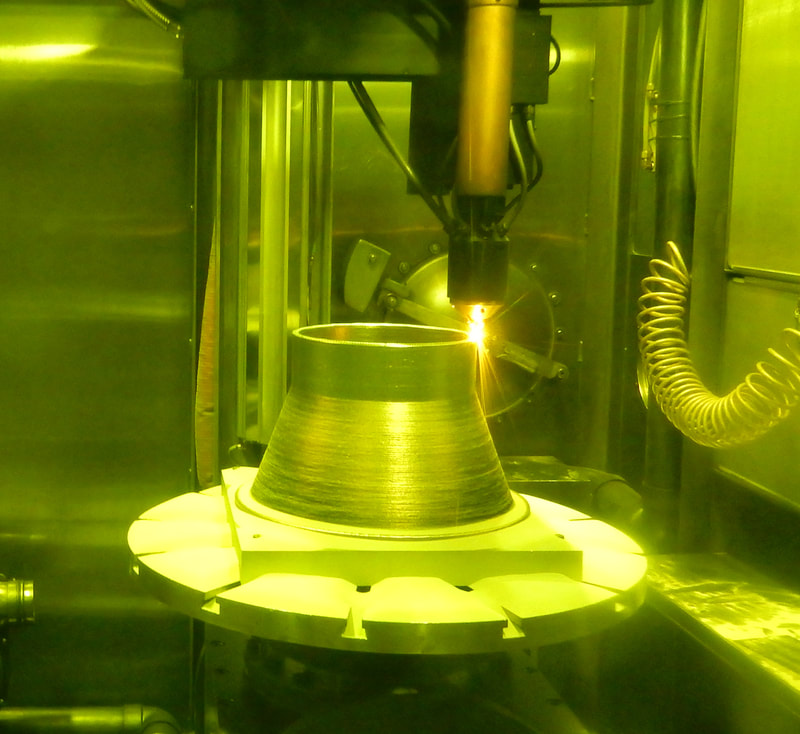

The Directed Energy Deposition (DED) process is commonly used to deposit "freeforms" of near-net-shape metal components, which are nearly 100% dense with mechanical properties comparable to wrought materials. Freeforms may be thin wall or thick masses of material (built to any thickness). Other similar terms for this process include additive manufacturing and 3D metal printing.

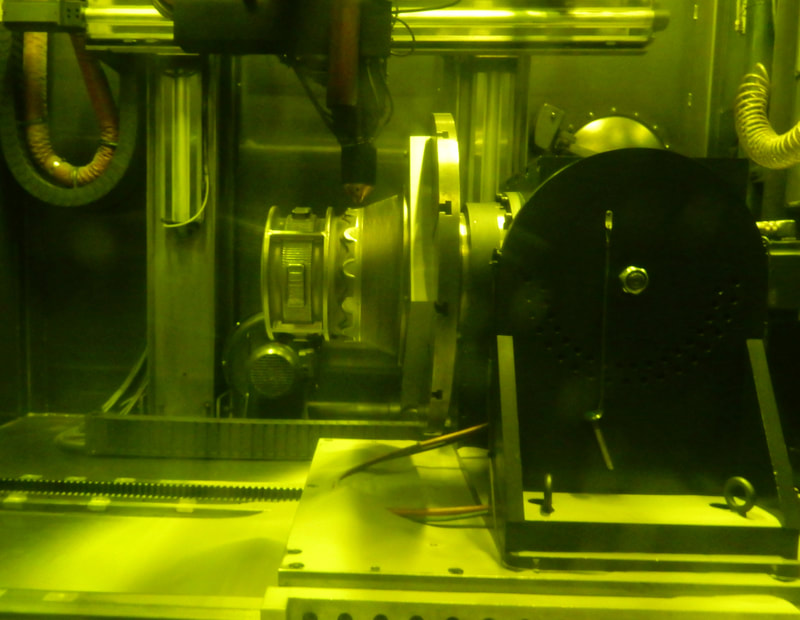

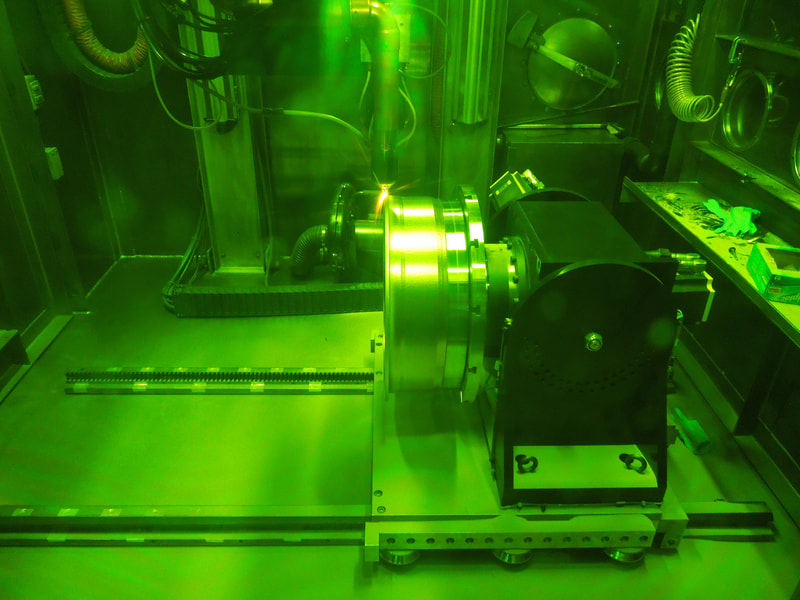

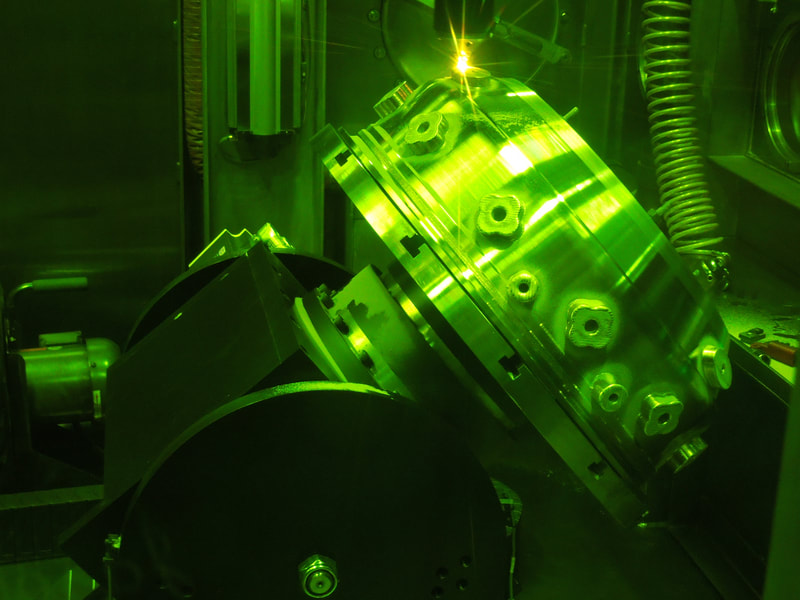

The process begins with a CAD file of the desired part. Next the CAD file is modified and processed by the system software where the tool path for the laser is generated. A target material (commonly referred to as a base plate) is required to start the build. The target base material may be incorporated into the final part or may simply be removed from the part when the freeform is complete. The freeform process occurs in an inert environment that protects against oxygen pickup in the molten material. Heat treatments and CMM scans of the completed freeform builds may be required depending on the specific application. The largest freeforms deposited to date include up to 60 inches long and others up to 7 feet in height.

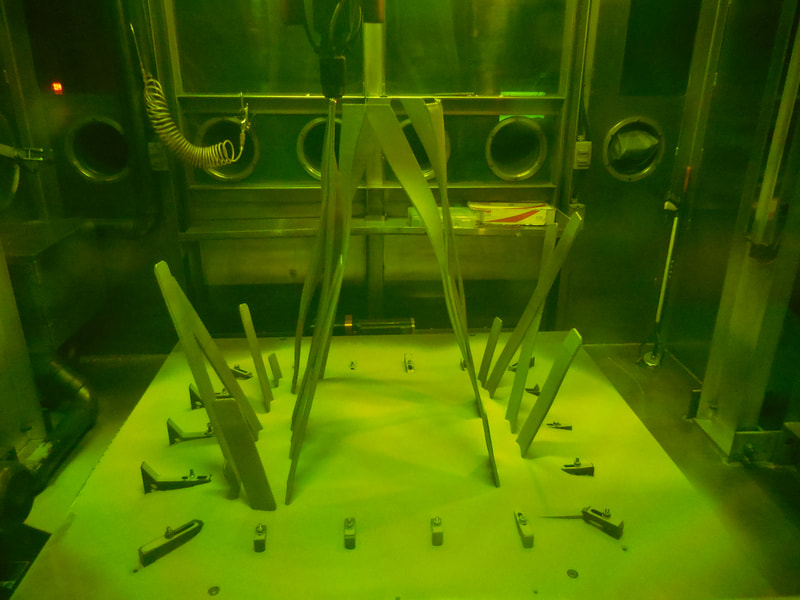

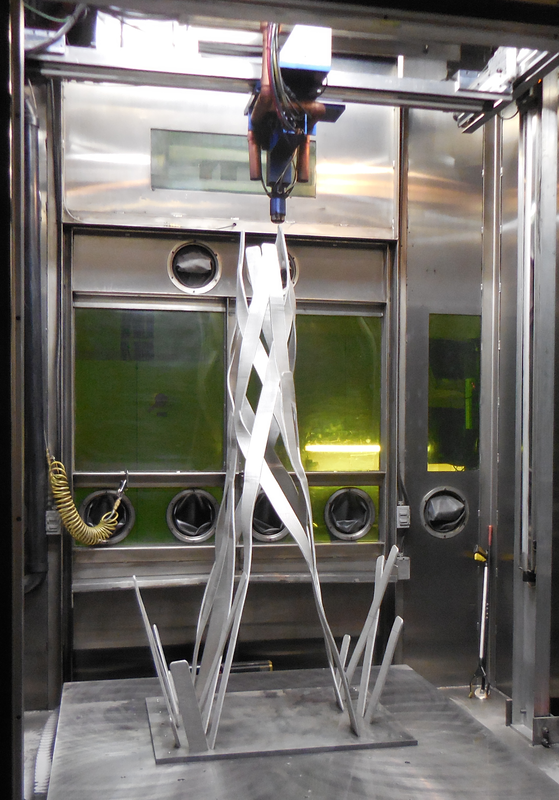

DED can manufacture components with high aspect ratio features such as structural components for aircraft bulk heads or spars, components with internal flow paths, or unique geometries that are nearly impossible for conventional machining. The cases below show a variety of DED freeforms.

The process begins with a CAD file of the desired part. Next the CAD file is modified and processed by the system software where the tool path for the laser is generated. A target material (commonly referred to as a base plate) is required to start the build. The target base material may be incorporated into the final part or may simply be removed from the part when the freeform is complete. The freeform process occurs in an inert environment that protects against oxygen pickup in the molten material. Heat treatments and CMM scans of the completed freeform builds may be required depending on the specific application. The largest freeforms deposited to date include up to 60 inches long and others up to 7 feet in height.

DED can manufacture components with high aspect ratio features such as structural components for aircraft bulk heads or spars, components with internal flow paths, or unique geometries that are nearly impossible for conventional machining. The cases below show a variety of DED freeforms.

Common Applications.

The applications are numerous, and we are still finding new applications each day.

|

|

|

Case Studies.

Channel Wall Nozzles |

|

IN 625 Dual Wall Duct |

|

IN 718 Case |

|

Ti-6Al-4V Freeform |

|

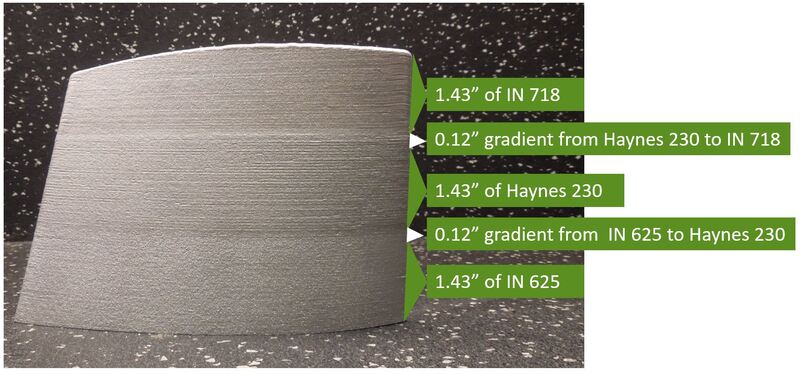

Gradients |

|

IN 718 Combustion

|

|