When operating any type of mechanical equipment with moving parts, repairing or rebuilding worn metal components is part of everyday life. Repairing worn components typically saves dollars over purchasing new ones. When a worn part is rebuilt, the potential also exists to repair that component in such a manner that it will have a longer wear life than a new part.

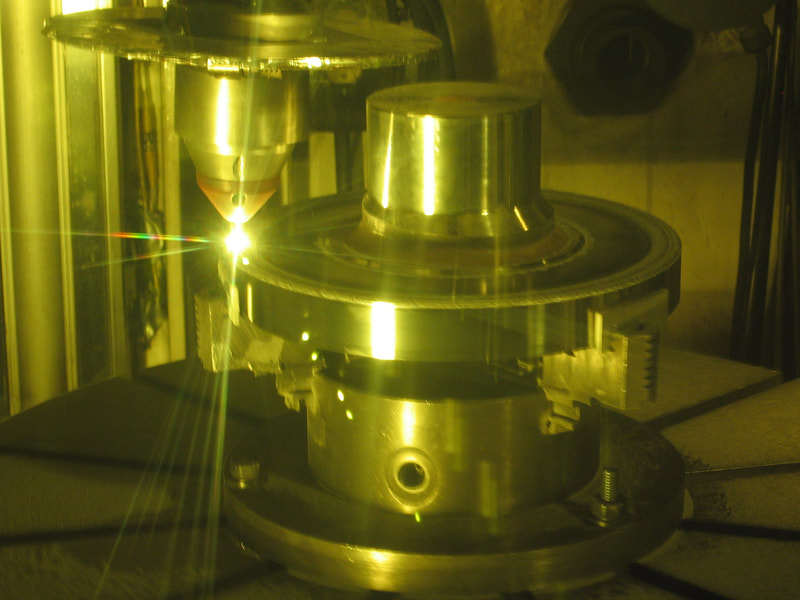

Directed Energy Deposition (DED) has a number of key benefits over other repair techniques that make it possible to repair some parts that were previously considered un-repairable. Using other techniques, either the part could not physically be repaired, or it was not economically feasible to perform the repair.

Some of the benefits of DED over other repair techniques are:

The key benefits of DED over other techniques are that it 1) creates a stronger bond and 2) inputs less heat to the part being repaired. The benefits of the stronger bond are obvious. The lower heat input means less distortion of the part during the repair process. These two benefits make the DED process unique.

Directed Energy Deposition (DED) has a number of key benefits over other repair techniques that make it possible to repair some parts that were previously considered un-repairable. Using other techniques, either the part could not physically be repaired, or it was not economically feasible to perform the repair.

Some of the benefits of DED over other repair techniques are:

- Metallurgical Bond versus Mechanical Bond

The DED process creates a metallurgical bond which is much stronger than the mechanical bond created using spray welding or plating techniques. - Low, Controlled Heat Input

The DED process creates very low and controllable heat input with minimal dilution and heat effect zones. - Minimal Stress and Distortion Created by Deposits

- Rapid Cooling Rates

- Cost Effective for Repairs and Manufacturing

The key benefits of DED over other techniques are that it 1) creates a stronger bond and 2) inputs less heat to the part being repaired. The benefits of the stronger bond are obvious. The lower heat input means less distortion of the part during the repair process. These two benefits make the DED process unique.

Common Applications.

|

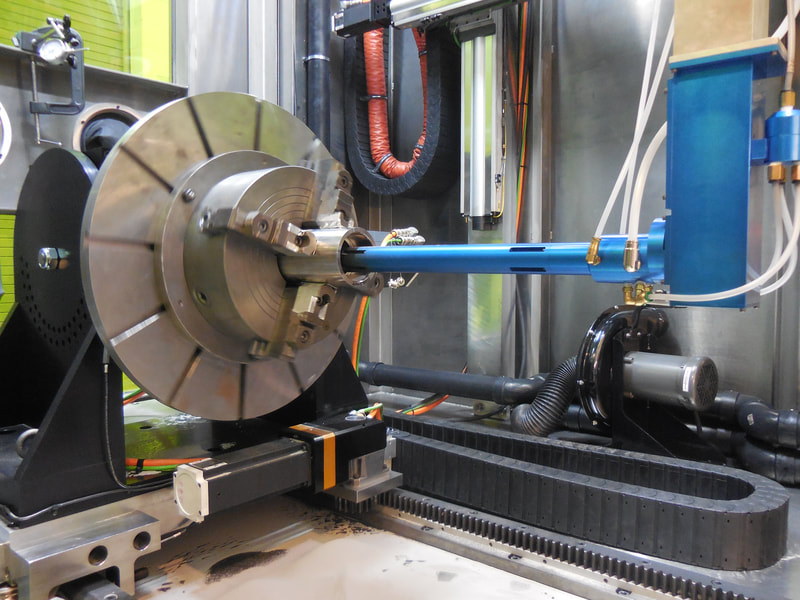

REPAIR

|

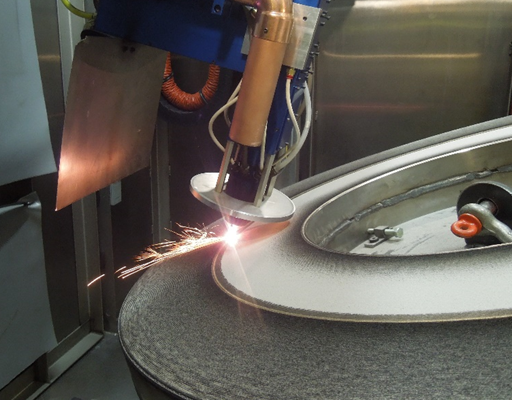

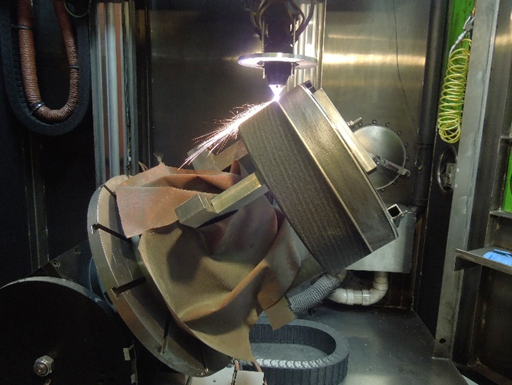

CLADDING

|

Case Studies.

4340

|

|

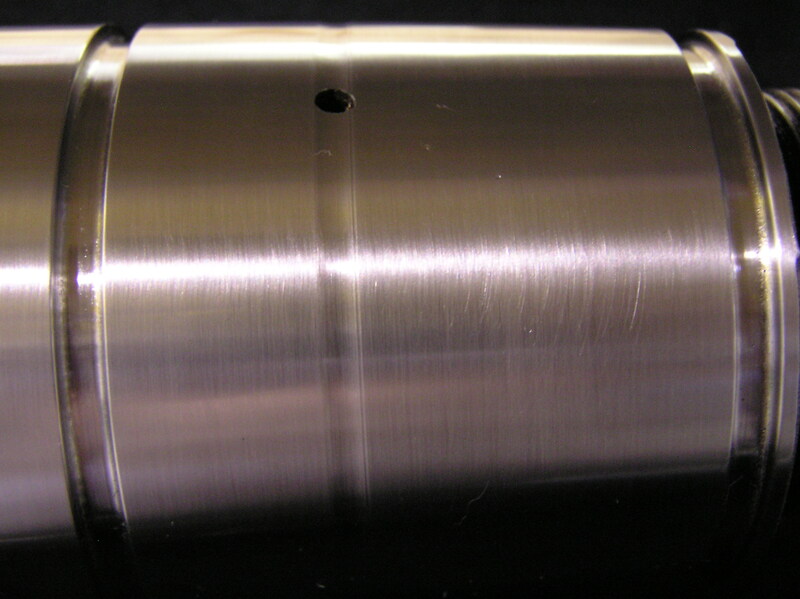

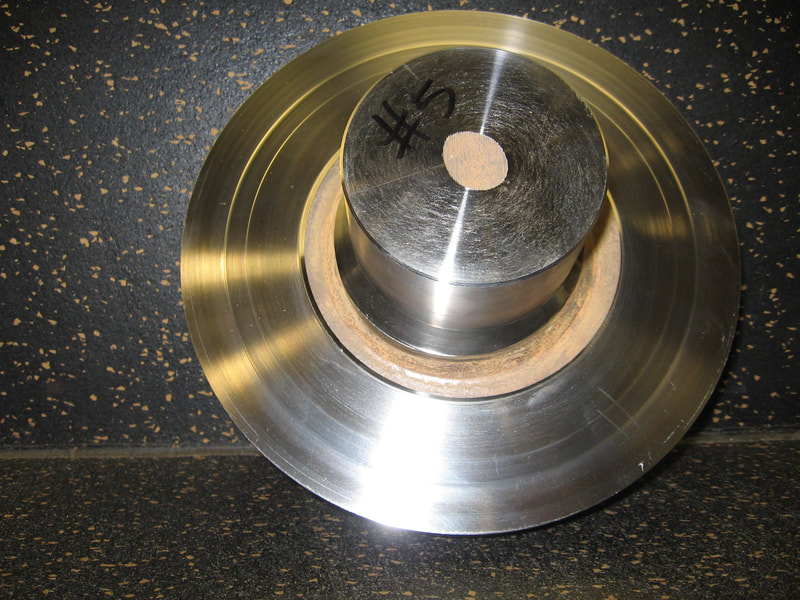

Bearing Surfaces |

|

ID Surface Repair |

|

SS Atomizer Shaft |

|

Ti-6Al-4V Driver Plate |

|